|

| September 11, 2018 | Volume 14 Issue 34 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

GM using Autodesk AI generative design software for lightweighting

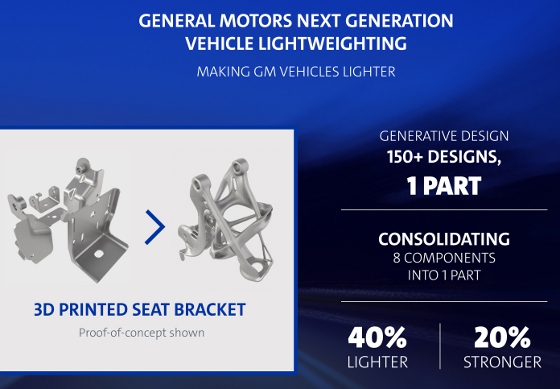

GM used generative design to produce this alien-looking seat bracket. Generative design uses cloud computing and AI-based algorithms to rapidly explore multiple part designs, generating hundreds of high-performance, often organic-looking geometric options based on goals and parameters set by the user.

General Motors is using new, advanced software design technology to introduce the next generation of vehicle lightweighting. The technology is key to developing efficient and lighter alternative propulsion and zero-emission vehicles.

GM is the first automaker in North America to use new generative design software technology from Bay Area-based software company Autodesk. It uses cloud computing and algorithms based on artificial intelligence (AI) to rapidly explore multiple permutations of a part design, generating hundreds of high-performance, often organic-looking geometric design options based on goals and parameters set by the user, such as weight, strength, material choice, fabrication method, and more. The user then determines the best part design option.

"This disruptive technology provides tremendous advancements in how we can design and develop components for our future vehicles to make them lighter and more efficient, said GM Vice President Ken Kelzer, Global Vehicle Components and Subsystems. "When we pair the design technology with manufacturing advancements such as 3D printing, our approach to vehicle development is completely transformed and is fundamentally different to co-create with the computer in ways we simply couldn't have imagined before."

GM is an industry leader when it comes to pushing into the next phase of vehicle lightweighting. The new design technology provides significantly more vehicle mass reduction and parts consolidation opportunities that cannot be achieved through traditional design optimization methods.

GM is utilizing the innovative technology on future product designs. GM and Autodesk engineers have applied generative design to produce a proof-of-concept part -- a seat bracket -- that is 40 percent lighter and 20 percent stronger than the original part. It also consolidates eight different components into one 3D-printed part.

The new seat bracket created using generative design is 40 percent lighter and 20 percent stronger than the original part. It also consolidates eight different components into one 3D-printed part.

As part of a multi-year alliance focused on innovation, GM and Autodesk will collaborate on projects involving generative design, additive manufacturing, and materials science. The plan is for executives and engineers from the two companies to participate in a series of onsite engagements to exchange ideas, what they've learned, and expertise. GM also has on-demand access to Autodesk's full portfolio of software and technical specialists.

"Generative design is the future of manufacturing," said Scott Reese, Autodesk Senior Vice President for Manufacturing and Construction Products. "Generative technologies fundamentally change how engineering work is done because the manufacturing process is built into design options from the start. GM engineers will be able to explore hundreds of ready-to-be-manufactured, high-performance design options faster than they were able to validate a single design the old way."

VIDEO: See generative design in action at GM.

On the additive manufacturing front, GM is no newbie. For more than three decades, the company has used 3D printing to create three-dimensional parts directly from digital data through successive addition of layers of material. GM possessed the first and has some of the auto industry's most comprehensive 3D-printing capabilities in the world with more than 50 rapid prototype machines that have produced more than 250,000 prototype parts over the last decade.

Since 2016, GM has launched 14 new vehicle models with a total mass reduction of more than 5,000 lb, or more than 350 lb per vehicle. Most of the weight reductions are a result of material and technology advancements. Of those models, more than half of the vehicles shed 300 lb or more, including the all-new 2019 Chevrolet Silverado, which reduced mass by up to 450 lb.

Eliminating mass in parts where material is not required for performance combined with parts consolidation yields benefits for vehicle owners too, including the potential for more interior space and vehicle content, increased range, and enhanced vehicle performance. It also paves the way for new features for customers and provides vehicle designers a canvas to explore designs and shapes not seen today.

Learn more about Autodesk generative design software here.

Source: General Motors

Published September 2018

Rate this article

View our terms of use and privacy policy